|

|

Air

Tightness to Avoid

Structural Damages |

|

|

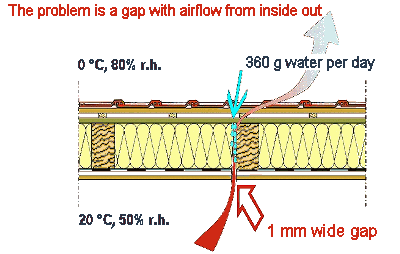

Air tightness is not

a mere nicety of energy saving construction, it is essential to

avoid construction damage. Gaps in the construction will lead to

substantial humidity transport by convection.

Everybody who plans to build a new house is well advised to pay attention to the air tightness of the envelope construction. Fixing the problem after the house is built can be difficult and costly.

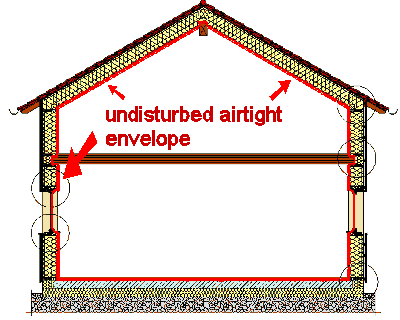

Of course details are important. But an envelope can be air tight only if it consists of a uniform, in tact, airtight enclosure wrapping around the whole house volume. In first step, for each element of the envelope, that part which is to achieve air tightness must be specified (e.g. the particle board or OSB in a roof construction). In a second step how the airtight layers of elements will be connected has to be detailed, assuring lasting air tightness. Insulation materials generally are NOT air tight (exception: foam glass). Therefor, the airtight envelope has to be designed and built separately. In timber constructions in most cases wooden composite boards are used (taped at the joints), in masonry construction a continuous inside plastering is sufficient. It is important, that the airtight envelope is continuous, without interruptions. This must be designed for, with particular attention to joints. Architects of passive houses are familiar with the design of high quality and enduring joints. There are special products to facilitate airtight external construction. The exhibition held during Passive House Conferences is a valuable source of innovative and effective solutions to achieving air tight construction. |

| The external envelope of a building should be as airtight as possible - this is true for conventional as well as for passive houses. It is the only means to avoid damage caused by condensation of moist, room warm air penetrating the construction (see the figure on the left hand side). Such damage not only occur in cold climates; in hot and humid climates the problem can occur from airflows from the outside to the inside. The cause is the same in both cases: a leaky building envelope. Drafts in living spaces are not tolerated by occupants any more: Therefor a very airtight construction is essential to fulfil modern thermal comfort expectations. Most building codes, worldwide, require airtight building envelopes and this is a reasonable and useful requirement. Air tightness should not be mistaken for insulation. Both qualities are essential characteristics of a high quality building envelope, but in most cases both have to be achieved independently:

Air tightness is an important, but not the most important requirement for energy efficient buildings (contrary to the impression given by some popular publications). Further, achieving air tightness should not be mistaken with the function of a "vapour barrier". The latter is a diffusion tight layer: An oiled paper e.g. is airtight, but it allows moisture vapour to pass through. Conventional room plastering (gypsum or lime plaster, cement plaster or reinforced clay plaster) is sufficiently airtight, but allows vapour diffusion. Infiltration can not guarantee good indoor air quality. Houses built in Germany after 1985, for example, are so airtight that infiltration alone is inadequate to assure acceptable indoor air quality. Yet, these houses are still at risk regarding moisture damage to the construction from moist room air exfiltration. A greater level of air tightness is needed and these houses must be considered as "untight". Their n50-air leakage varied between 4 and 10 h-1. The consequences are draft-discomfort and moisture damage to the construction. The construction was too leaky to avoid exfiltration caused damages - but too tight for sufficient infiltration to maintain room air quality. The new 2001 German building code ("EnEV" Energy Saving Standard) for the first time addresses the air tightness of new constructions. Without a ventilation system the n50-airchange-values have to be less than 3 h-1, with ventilation systems 1.5 h-1. From the experience in low energy houses we recommend tighter construction (lower n50) leakages. In passive houses far better n50 leakage rates are frequently achieved. The requirement is n50 not greater than 0.6 h-1. In practice values between 0.2 und 0.6 h-1 have been measured in passive houses. Air tightness is not a question whether a construction is massive or light weight. Built passive houses using masonry, timber, prefabricated, lost frame with concrete and steel bearing structure have achieved this superior level of air tightness. Sören Peper, a scientist at the Passive House Institute, proved by a systematic field study that n50 leakage rates between 0.2 and 0.6 h-1 can reproducibly be achieved today. Careful design and accurate workmanship are the prerequisites to success. Construction details needed to achieve tightness are available for all important joint and envelope penetration situations. A key principle is maintaining "an undisturbed, airtight envelope", which can be recognised by the "rule of the red line" (see the section in the third figure on the left hand side). 11th Conference on Passive Houses: The experience of design and construction of an airtight building envelope will be discussed in Workshop 4: "Innovation in Passive Houses Envelopes and Systems ". Products for achieving sustainable, airtight envelopes can be viewed and discussed at the parallel exhibition and there will also be a demonstration of a Blower-Door-Test. (updated: 2006-09-23

WF - thanks to Robert Hastings for proof reading of

the 1st edition - |